Gubersail Tire Continues to Optimize Standardized Morning Meeting Mechanism to Enhance Frontline Execution and Safety Awareness

Standardizing Processes for Quality and Efficiency, Bridging the “Last Mile” of Information Delivery

On April 24, 2025, Gubersail Tire’s Production Department organized a joint morning meeting training session in the molding workshop, co-chaired by the molding workshop’s shift leader and the equipment department’s section chief, with frontline employees from both departments participating. This training focused on deepening and optimizing the standardized morning meeting mechanism, aiming to further improve pre-shift communication efficiency, strengthen safety management awareness, and elevate frontline execution to a new level.

Gubersail Tire has long implemented a morning meeting system in various workshops, forming a pre-shift communication mechanism of “fixed time, fixed location, fixed personnel, and fixed procedures.” This morning meeting training in the molding workshop, while retaining the original procedures, focused on strengthening key content, improving interactive mechanisms, and closing the loop on problem execution, reflecting a continuous effort to advance morning meeting management from “standardization” to “high efficiency.”

Focusing on Key Content to Strengthen Safety and Production Synergy

The meeting was held punctually before the start of the morning shift, with a total duration controlled within 15 minutes, aiming for “short and precise, fast and accurate” for efficient execution. The morning meeting began with roll call and labor protection inspections, ensuring that every employee was in optimal condition for work.

Subsequently, the shift leader organized employees to review the previous day’s production situation, reported on output, quality indicators, and on-site problem handling, and pointed out key process nodes and quality control points that require continuous attention. Problem feedback adhered to the principle of “clarifying on the same day, clearly defining responsibilities, and following up on rectifications,” promoting a closed-loop management system on site.

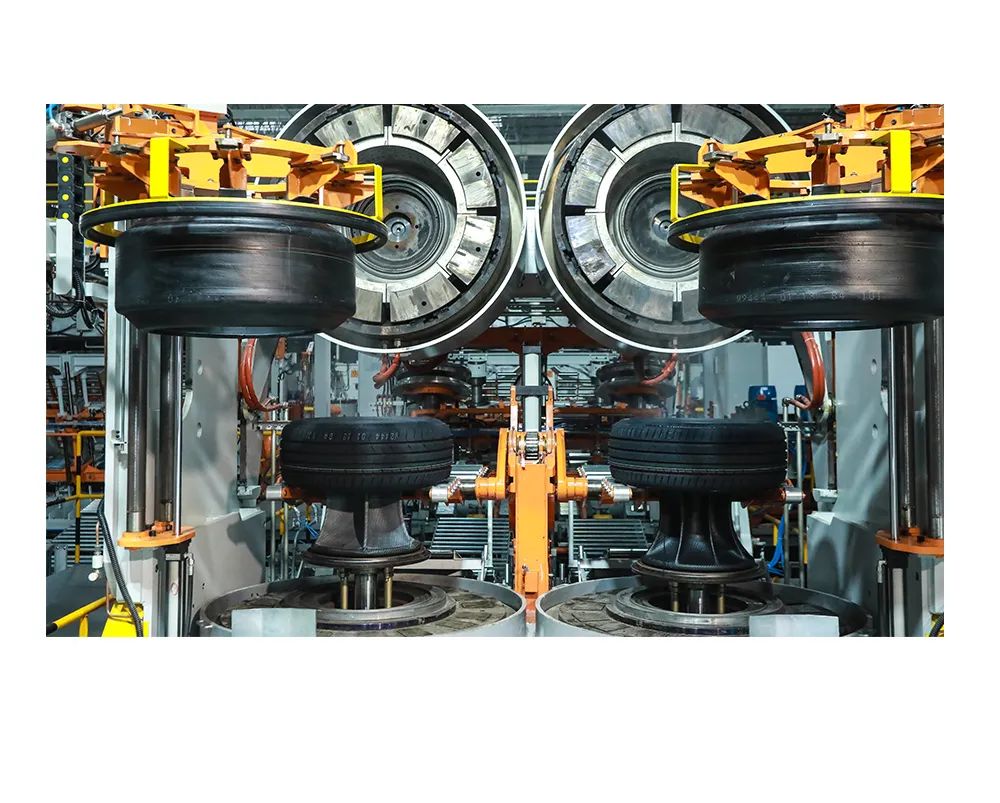

The section chief of the equipment department explained the day’s key equipment operation status, safety precautions, and maintenance plans, with particular emphasis on the operating procedures and risk prevention and control measures for high-temperature equipment such as vulcanizers, further strengthening employees’ safety awareness and ensuring stable and controllable production processes.

During the task deployment phase, the shift leader, in conjunction with the day’s production plan, clearly broke down process adjustments, job assignments, and quality objectives, ensuring that every employee had “clear tasks, clear standards, and accurate operations.” A Q&A and suggestion collection session was set up at the end of the meeting to encourage employee participation and feedback, enhancing the team collaboration atmosphere.

Regular Mechanism Shows Results, Morning Meeting Quality Steadily Improves

Long-term adherence to the standardized morning meeting mechanism has made pre-shift communication in each workshop increasingly efficient. Data shows that the average duration of morning meetings in each workshop has been compressed from the original 25 minutes to 12 minutes, making communication more precise and the pace more compact. At the same time, driven by daily safety education and problem reviews, responses to production anomalies are faster, employee violations are significantly reduced, and team collaboration efficiency continues to improve.

This joint morning meeting training, co-chaired by the “section chief + shift leader,” is both a transmission of management experience and a re-strengthening of team execution. Gubersail Tire will continue to deepen the connotation and extension of the standardized morning meeting mechanism, promote modularization of morning meeting content and visualization of management tools, and facilitate smoother information transmission, more powerful execution, and more timely problem response, thereby solidifying the management foundation for creating an efficient, safe, and orderly production site.