Tyre compound

Exclusive tyre compound technology maximizes the balance of rolling resistance, wet skid resistance and wear resistance.

The overall use of solution-polymerized styrene-butadiene rubber: the rolling resistance of the tires is reduced by about 30%, the wet skid resistance is improved by about 3%, the wear resistance is enhanced by about 11%, and the fuel consumption is reduced by 5% to 6%.

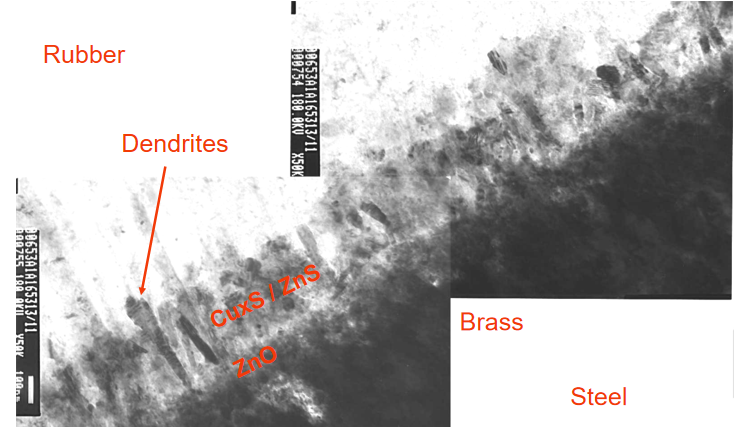

The cobalt salt bonding system (cobalt boroylated) is adopted to enhance the initial bonding between the steel cord with the bundle layer and the rubber, and to improve the steel wire's resistance to moisture and heat as well as salt water aging.

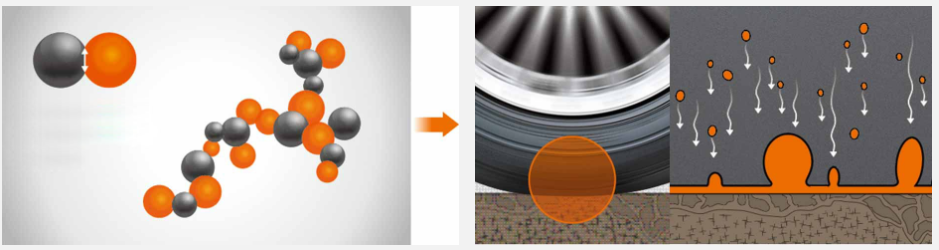

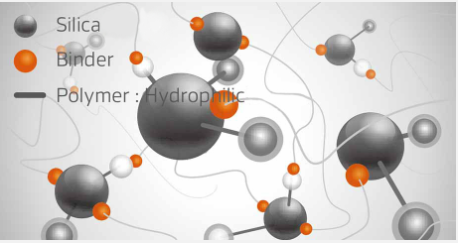

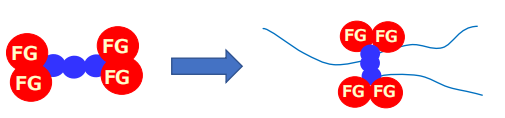

The formula uses highly filled and highly dispersed silica to reduce the rolling resistance of tires. Functionalized polymers are adopted to enhance the bond between water-resistant polymers and hydrophilic silicon, thereby achieving excellent wear resistance and low rolling resistance (LRR). By adopting a highly dispersed silica formula, the contact surface between the tire and the ground is increased, achieving the best Hydrophilic effect, thereby further improving the braking performance of the tire in wet conditions.

Tyre compound

Exclusive tyre compound technology maximizes the balance of rolling resistance, wet skid resistance and wear resistance.

The tread rubber adopts a new type of high-molecular-weight SSBR end modification technology product, which enhances the bonding ability with silica, enabling the tire to simultaneously possess low rolling resistance, high wet grip and wear resistance.